Additive Masterbatch |

At Shreevi Polymers, our Additive Masterbatch is designed to enhance the performance and functionality of your plastic products. Our range of additive masterbatches includes solutions for UV stabilization, flame retardancy, anti-static properties, and more, ensuring your products meet the highest standards of durability and safety. Whether you need to protect against UV degradation, improve processability, or add specific functionalities, our additive masterbatches provide the reliability and efficiency you need for optimal product performance.

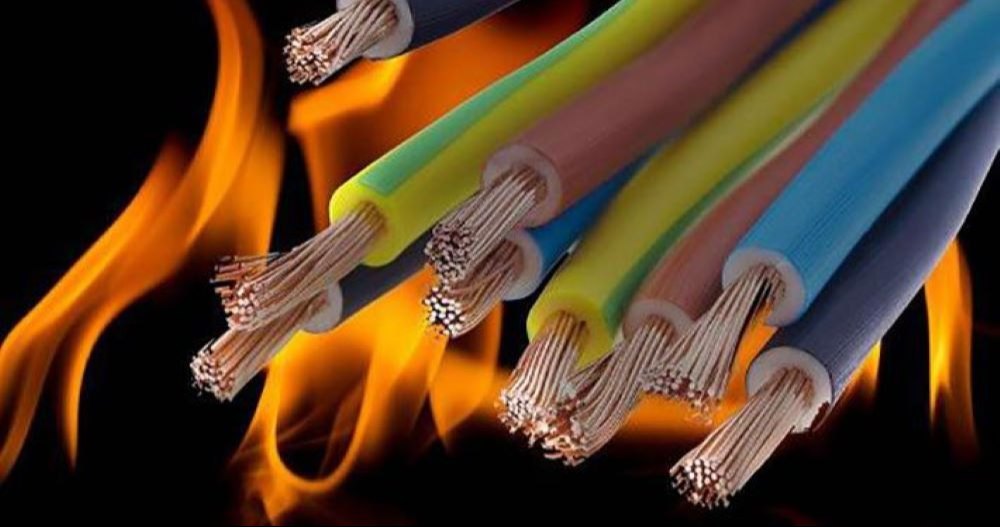

Flame Retardants

Flame retardants serve as essential protectors, safeguarding polymers from ignition and slowing the spread of flames in the event of a fire. By incorporating flame-retardant masterbatch, you enhance the safety and resilience of polymer-based materials, ensuring they meet stringent fire safety standards and retain their integrity even in high-risk environments.

Anti-Slip

Antislip Masterbatches introduce polymer particles to roughen the surface of films, creating a natural non-slip texture post-production. This feature is particularly beneficial for bag manufacturers, offering enhanced grip. Comprising specialized additives within PE carrier resins, this masterbatch boosts the coefficient of friction between polyethylene films or sheets.

Agricultural Films

Pipes and Fittings

Outdoor Furniture

Protective Visors

Automotive Components

Labels and Tapes

Packaging Materials